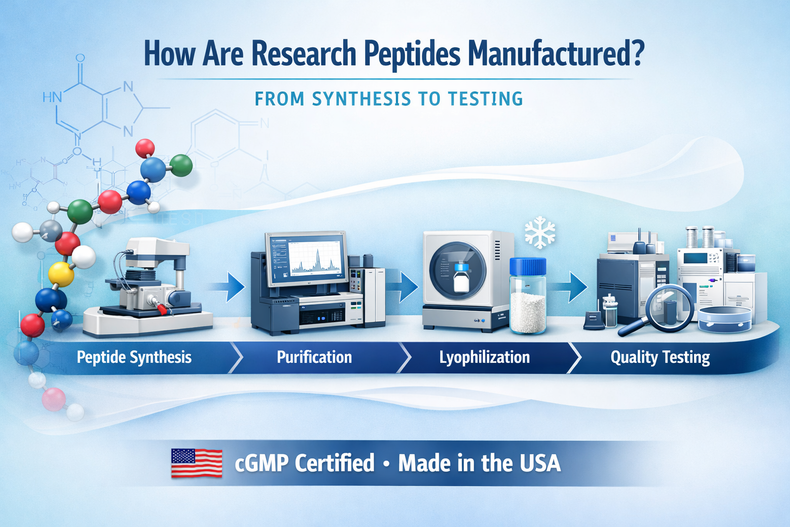

From Synthesis to Testing in cGMP USA Facilities

Key Takeaways

- Research peptides are manufactured through a precise, multi-step chemical process

- Solid-phase peptide synthesis (SPPS) is the industry standard for accuracy and control

- cGMP peptide manufacturing ensures consistency, traceability, and quality oversight

- Purification and analytical testing are essential for peptide quality control

- USA peptide manufacturing offers regulatory transparency and reliable batch testing

Introduction

When working with research peptides, quality begins long before a vial reaches the laboratory. The manufacturing process — from synthesis to final testing — directly determines peptide purity, stability, and reliability.

Understanding how peptides are manufactured allows researchers to evaluate suppliers more critically, avoid low-quality products, and ensure reproducible experimental results. This article explains the full peptide synthesis process, with a focus on cGMP peptide manufacturing, batch testing, and quality control standards used by reputable USA-based manufacturers.

Understanding the Basics of Peptide Manufacturing

Peptides are short chains of amino acids linked by peptide bonds. While structurally simple compared to proteins, producing peptides at research-grade quality requires highly controlled chemistry and strict procedural discipline.

Modern peptide manufacturing generally includes:

- Chemical synthesis of the amino acid sequence

- Removal of synthesis byproducts

- Purification to isolate the target peptide

- Stabilization for storage

- Analytical verification and batch documentation

Each stage plays a critical role in determining final peptide quality.

The Peptide Synthesis Process

Solid-Phase Peptide Synthesis (SPPS)

Most research peptides are produced using solid-phase peptide synthesis (SPPS). This method allows peptides to be assembled one amino acid at a time on a solid resin support, offering exceptional precision and reproducibility.

SPPS is widely used because it:

- Enables accurate sequence control

- Reduces side reactions

- Supports both short and complex peptides

Scales efficiently for research production

Step 1: Resin Attachment

Synthesis begins by anchoring the first amino acid to a solid polymer resin. This resin acts as a stable foundation for building the peptide chain and allows excess reagents to be washed away between steps.

Step 2: Sequential Amino Acid Coupling

Amino acids are added sequentially according to the target peptide sequence. To prevent unwanted reactions, functional groups are temporarily protected using chemical protecting groups such as Fmoc or Boc.

Each coupling reaction forms a new peptide bond, extending the chain by one amino acid.

Step 3: Deprotection Cycles

After each coupling, the protecting group is removed to expose the reactive site for the next amino acid. This cycle of coupling and deprotection repeats until the full peptide sequence is assembled.

Step 4: Cleavage and Final Deprotection

Once synthesis is complete, the peptide is chemically cleaved from the resin and all remaining protecting groups are removed. The result is a crude peptide containing the target sequence along with synthesis-related impurities.

cGMP Peptide Manufacturing Standards

Current Good Manufacturing Practice (cGMP) guidelines establish a framework for producing peptides with consistent quality and full traceability.

In USA peptide manufacturing facilities, cGMP-aligned processes typically include:

Quality Systems and Documentation

- Standard Operating Procedures (SOPs)

- Batch records covering every production step

- Controlled deviation and corrective action processes

Environmental Controls

- Cleanroom environments

- HEPA-filtered air systems

- Continuous monitoring of temperature, humidity, and particulates

Equipment and Personnel Controls

- Qualified and calibrated equipment

- Trained and authorized manufacturing staff

- Documented maintenance and validation

These systems help ensure that peptides are produced under controlled, repeatable conditions.

Peptide Purification

Crude peptides contain incomplete sequences, truncated chains, and chemical byproducts. Purification is required to isolate the desired peptide.

High-Performance Liquid Chromatography (HPLC)

HPLC is the primary method used for peptide purification.

- Reverse-phase HPLC (RP-HPLC) separates peptides based on hydrophobicity

- Purified fractions are collected and analyzed

- Research-grade peptides typically reach ≥95% purity, with premium grades approaching 99%

Additional purification methods may be used depending on peptide complexity.

Lyophilization and Stabilization

After purification, peptides are commonly lyophilized (freeze-dried) to improve stability and shelf life.

Lyophilization removes water without damaging peptide structure, producing a dry powder suitable for long-term storage and accurate reconstitution. Stabilizing excipients may be added to improve handling and consistency.

Peptide Batch Testing and Quality Control

Before release, each batch undergoes comprehensive peptide batch testing to verify identity, purity, and quality.

Common Analytical Tests

- Mass spectrometry (MS): Confirms molecular weight and sequence accuracy

- Analytical HPLC: Measures purity and detects impurities

- Amino acid analysis (AAA): Confirms composition

- Peptide content determination: Ensures accurate dosing

- Endotoxin testing: Required for sensitive research applications

- Sterility testing: Performed when applicable

These tests form the foundation of robust peptide quality control.

Certificate of Analysis (CoA)

Each peptide batch should include a Certificate of Analysis, detailing:

- Peptide sequence and molecular weight

- Purity percentage

- Testing methods used

- Storage and handling recommendations

Batch-specific CoAs provide transparency and allow researchers to verify product quality independently.

Why USA Peptide Manufacturing Matters

Choosing peptides manufactured in the United States offers several advantages:

- Strong regulatory oversight

- Transparent documentation and traceability

- Consistent batch-to-batch quality

- Reduced supply chain uncertainty

- Access to technical support

For research environments that depend on reproducibility, these factors are critical.

Conclusion

From amino acid assembly to final batch testing, peptide manufacturing is a highly controlled, multi-step process. The peptide synthesis process — when performed in cGMP-aligned, USA-based facilities — ensures that research peptides meet strict quality, purity, and consistency standards.

Understanding how research peptides are manufactured enables researchers to make informed purchasing decisions, protect experimental integrity, and maintain confidence in their results. Manufacturing quality is not a secondary detail — it is the foundation of reliable peptide research.